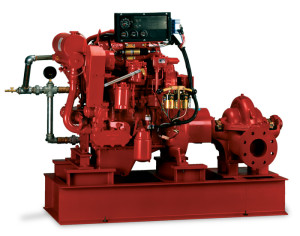

Diesel Engine Fire Pumps

Key Features – Diesel Engine Fire Pumps

- UL Listed/FM Approved/NFPA-20 Design

- For Commercial, Industrial and Marine Use

- Diesel and Electric Driven Available

- Lower Initial Cost

- Quicker Delivery with Red Hot Quick Ship Program

- Ease of Maintenance

Diesel Engine Fire Pumps Horizontal split case pumps are the most common type of fire pump. These pumps are specifically designed and tested for fire service applications where reliability of performance is of vital importance. Split case pumps are characterized by:

• Easy access to all working parts;

• Rugged construction;

• Liberal water passages; and

• Efficient operation.

Split case fire pumps are specified when the source of water is located above the surface of the ground and provides a positive suction pressure to the pump at any performance point. Single-stage or multistage pumps are available dependent upon discharge pressure requirements. Aurora split case fire pumps are built per the rigid standards of NFPA 20 and are listed by Underwriters Laboratories (UL) and approved by Factory Mutual (FM). Available in a broad range of operating pressures and flows from a minimum of 250 GPM, Aurora split case pumps can be driven by either an electric motor or diesel engine. Aurora’s UL-Listed, FM-Approved fire pump packages also include the system controller, with a full range of options and accessories available to complete the NFPA-compliant fire pump package. In addition to horizontal split case pumps, Aurora diesel engine fire pumps also offers split case performance in a vertical format. Vertical fire pumps provide distinct advantages over horizontal pump constructions.

• Less floor space is required.

• In-line piping arrangement allows piping in any direction in most cases.

• Elevated motor protects against potential flooding if the pump station is in a low area.

• Components are register-fitted to prevent misalignment

Standard Features – Diesel Engine Fire Pumps

• Bronze fitted pump construction

• Bronze shaft sleeves

• Bronze case wearing rings

• Dynamically balanced impellers

• Stainless steel impeller key

• Carbon steel shaft

• Corrosion-resistant lantern rings*

• Bronze stuffing box bushings

• Bronze or stainless steel glands

• Interwoven graphite-impregnated T.F.E. packing rings

• Cast integral bearing arms (most models)

• Regreaseable ball bearings

• Double row thrust bearing (outboard side)

• Upper casing lifting lugs

• Water slingers and grease seals

• Hydrostatic and Certified Performance test

• Coupling guard

• Suction and discharge gauges with shutoff cocks

• Automatic air release valve

• Casing relief valve (electric driven units only)